From appliances, autos and aircraft, to the endeavors of our space exploration program, Imagineering Finishing Technologies is the trusted partner for non-destructive testing and inspection services. We have a distinguished list of prime contractors that look to us for our knowledge of applications and our engineering expertise.

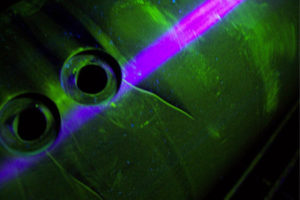

Our etching and inspection process identifies and detects discontinuities and imperfections in ferrous, non-ferrous, ferromagnetic, and non-metallic materials, and can be utilized in all phases of product design and manufacturing. We employ a total of 9 processes to ensure detection of defects and hidden flaws, including porosity, inclusions, folds and seams, tool marks, and cracks. To ensure paramount safety in your products, please contact Imagineering Finishing Technologies or see below for additional information.